Ball Valves

Ball valves are mechanical valves that use a spherical closure element (the ball) to control the flow of fluids through a pipeline.

Ball Valves are versatile, reliable, and widely used in various industries and applications for their efficient flow control and tight sealing capabilities. Their simple design, ease of operation, and durability make them a popular choice for fluid handling systems.

There are four main types of :

- Forged Ball Valves

- Floating Ball Valves

- Trunnion Ball Valves

- Lined Ball Valves

Applications:

Ball valves are widely used in various industries and applications due to their versatility, reliability, and ease of operation. They are commonly used in water and wastewater systems, oil and gas pipelines, chemical processing plants, power generation facilities, HVAC systems, and residential plumbing systems.

Materials of Construction:

Ball valves are available in various materials to suit different applications and operating conditions. Common materials include stainless steel, brass, bronze, carbon steel, PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), and exotic alloys. The choice of material depends on factors such as the type of fluid being handled, temperature, pressure, corrosion resistance requirements, and compatibility with other system components.

Advantages:

- Quick On/Off Operation: Ball valves provide fast and reliable shutoff with a simple quarter-turn operation.

- Tight Sealing: Ball valves provide excellent sealing capabilities, even in high-pressure or high-temperature applications.

- Low Pressure Drop: Ball valves typically have a low pressure drop compared to other types of valves, resulting in minimal flow resistance.

- Versatility: Ball valves can handle a wide range of fluids, including gases, liquids, and slurries, making them suitable for various applications.

- Durability: Ball valves are durable and resistant to wear, corrosion, and erosion, resulting in long service life and low maintenance requirements.

| Design Standards : |

|

|---|---|

| Testing Standards : |

BS 5146 |

| Size Ranges : |

2"-16" (DN50-DN400) |

| Class : | 150-2500 |

| Material of Construction: | WCB, WCC, WC6, WC9, C5, C12, LCB,LCC, CF8, CF8M, etc. |

| Face to Face: | As per ASME B16.10 |

| Actuation: | Manual, Gear, etc. |

| End Connection: | ANSI B16.5(Raised Flanged), ANSI B16.25(Butt Weld), ANSI 16.11(Socket Weld), ANSI B1.20.1(Screwed End) |

Types Of Ball Valves

Forged Ball Valves

Forged ball valves are a type of ball valve constructed using forged materials, typically metal alloys, to provide enhanced strength, durability, and reliability in high-pressure and high-temperature applications.

Design and Construction:

- Forged ball valves feature a spherical ball with a through-hole (port) that rotates within the valve body to control the flow of fluid. When the ball's port is aligned with the flow direction, the valve is open, allowing fluid to pass through.

- When the ball is rotated 90 degrees, the port is perpendicular to the flow direction, and the valve is closed, preventing flow. Forged ball valves can have either a full port or reduced port design, depending on the size of the ball opening.

- Forged ball valves are constructed using forged materials, which are produced by applying high pressure and temperature to shape metal into desired forms.

- The main components of forged ball valves typically include a body, ball (closure element), stem, seat, and end connections. The forged construction provides superior mechanical properties compared to cast valves, making them suitable for demanding applications.

Materials of Construction:

- Forged ball valves are available in a wide range of materials, including carbon steel, stainless steel, alloy steel, and other exotic alloys.

- The choice of material depends on factors such as the fluid being handled, temperature, pressure, corrosion resistance requirements, and compatibility with other system components.

Standards and Certifications:

- Forged ball valves are manufactured in accordance with industry standards and specifications such as API (American Petroleum Institute), ASME (American Society of Mechanical Engineers), ASTM (American Society for Testing and Materials), ANSI (American National Standards Institute), and others.

- They may also meet specific regulatory requirements or certifications for use in critical applications or hazardous environments.

Floating Ball Valves

Floating ball valves are a type of ball valve where the ball is not fixed in place but instead floats between the two seats.

Design and Construction:

- Floating ball valves consist of a ball with a through-hole (port) that is not fixed to the valve body but is instead free to move within the valve cavity.

- The upstream seat provides additional sealing when the valve is in the closed position. When the valve is open, the fluid pressure pushes the ball against the downstream seat, allowing flow through the port.

- The ball is held in place by the downstream seat, which creates a seal against the ball when the valve is closed.

Materials of Construction:

- Floating ball valves are available in a variety of materials to suit different application requirements, including carbon steel, stainless steel, alloy steel, and other exotic alloys.

- The choice of material depends on factors such as the fluid being handled, temperature, pressure, corrosion resistance requirements, and compatibility with other system components.

Standards and Certifications:

- Floating ball valves are manufactured in accordance with industry standards and specifications such as API (American Petroleum Institute), ASME (American Society of Mechanical Engineers), ASTM (American Society for Testing and Materials), ANSI (American National Standards Institute), and others.

- They may also meet specific regulatory requirements or certifications for use in critical applications or hazardous environments.

Trunnion Mounted Ball Valves

Trunnion mounted ball valves are a type of ball valve distinguished by the presence of a fixed trunnion, which provides additional support for the ball.

Design and Construction:

- Trunnion mounted ball valves consist of a ball with a through-hole (port) that is supported by trunnions (fixed shafts) at the top and bottom of the ball.

- These trunnions are mounted within the valve body and provide additional support and stability for the ball, particularly in larger valve sizes and high-pressure applications.

- The ball is held in place by the valve seats, which create a seal against the ball when the valve is closed.

Applications:

- Trunnion mounted ball valves are used in various applications where reliable flow control and shutoff are required, particularly in medium to high-pressure environments.

- hey are commonly installed in pipelines, process equipment, steam lines, and other fluid handling systems across industries such as oil and gas, petrochemical, power generation, refining, and chemical processing.

Standards and Certifications:

- Trunnion mounted ball valves are manufactured in accordance with industry standards and specifications such as API (American Petroleum Institute), ASME (American Society of Mechanical Engineers), ASTM (American Society for Testing and Materials), ANSI (American National Standards Institute), and others.

- They may also meet specific regulatory requirements or certifications for use in critical applications or hazardous environments.

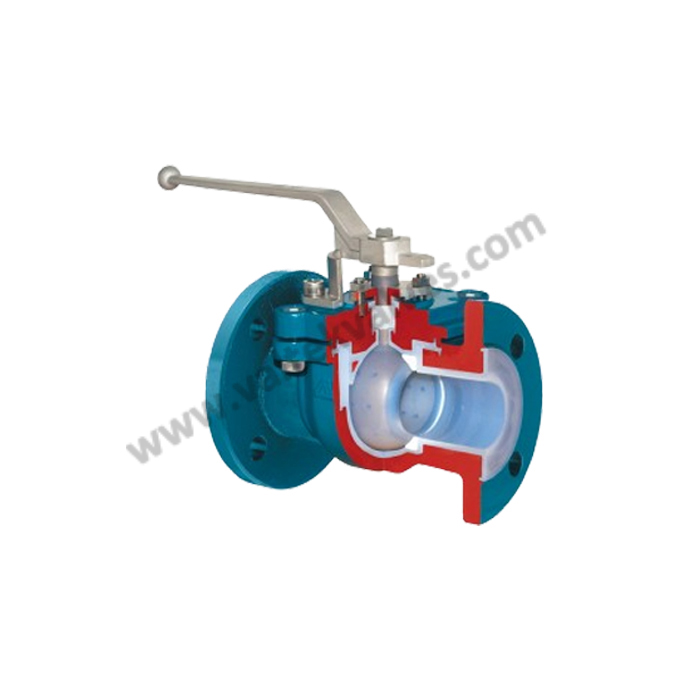

Lined Ball Valves

Lined ball valves are a type of ball valve designed with a lining material on the internal surfaces of the valve to provide corrosion resistance and prevent fluid contact with the valve body and components.

Design and Construction:

- Lined ball valves operate similarly to standard ball valves, with the ball rotating within the valve body to control the flow of fluid. When the ball's port is aligned with the flow direction, the valve is open, allowing fluid to pass through.

- When the ball is rotated 90 degrees, the port is perpendicular to the flow direction, and the valve is closed, preventing flow. Lined ball valves can have either a full port or reduced port design, depending on the size of the ball opening.

Materials of Construction:

- Lined ball valves consist of a ball with a through-hole (port) that is surrounded by a lining material, typically PTFE (polytetrafluoroethylene) or other fluoropolymer materials.

- The lining covers the internal surfaces of the valve body, ball, and seats, providing corrosion resistance and preventing contact between the fluid and the valve body material.

- The valve body and other components are usually made of materials such as carbon steel, stainless steel, or ductile iron.

Standards and Certifications:

- Lined ball valves are manufactured in accordance with industry standards and specifications such as ASME B16.34, API 6D, ISO 17292, and others.

- They may also meet specific regulatory requirements or certifications for use in critical applications or hazardous environments.

One of the best supplier i could ever found. Plus you are the best and cheapest.